Streamlining Processes for Maximum Efficiency

Lean Manufacturing

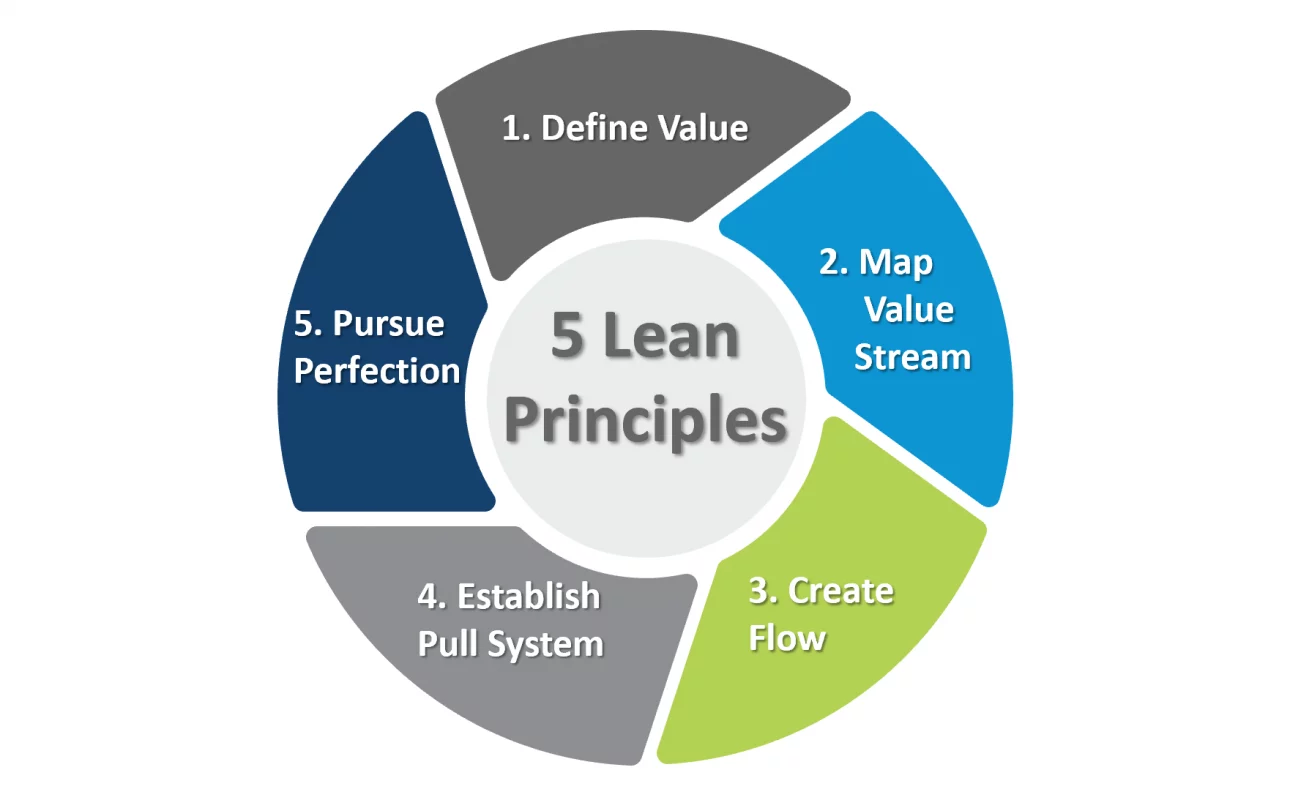

Lean manufacturing is a production philosophy focused on minimizing waste while maximizing value to the customer. Originating from the Toyota Production System, Lean manufacturing aims to eliminate inefficiencies, streamline workflows, and deliver high-quality products with minimal waste and cost.

| Value Stream Mapping | Identifies all the actions in a process to determine which are value-adding and which are waste. |

|---|---|

| Kanban | A visual inventory system that helps manage the production flow by signaling when to reorder materials or parts. |

| 5S | A methodology for organizing a workspace, which stands for Sort, Set in order, Shine, Standardize, and Sustain. |

| Continuous Improvement (Kaizen) | A philosophy that encourages continuous, small improvements in processes. |

Example: The Case of Nike’s Lean Transformation

Nike, one of the world’s largest footwear manufacturers, successfully applied Lean principles to transform its supply chain and improve its efficiency. Prior to adopting Lean, Nike faced issues with excessive inventory and long lead times in manufacturing. By implementing value stream mapping and the Kanban system, Nike was able to eliminate bottlenecks, reduce cycle times, and manage inventory more effectively.

Results:

- Reduced production lead times by 30%.

- Decreased inventory levels, saving millions of dollars in carrying costs.

- Improved on-time delivery to customers.

Real-World Results:

- Lead Time Reduction: Many manufacturers, including Toyota, have achieved significant reductions in production lead time through Lean practices. For example, companies have reduced lead times by up to 50% by optimizing their supply chain, reducing inventory, and eliminating bottlenecks.

- Cost Savings: The elimination of waste in production leads to substantial cost reductions. Companies like Nike and Boeing have saved millions by reducing unnecessary processes and improving operational efficiency.